Cam phasers may sound like futuristic technology out of science fiction, but it’s a fact – this technology is in your customers’ engines right now, and it’s critical that your team isn’t “stunned” by the challenges.

It’s not actually “new” – different types of variable valve timing or VVT have been used in vehicles since the ‘60s, really gaining popularity with Honda’s VTEC engine in the late 1980s. Since then, VVT has become the dominant underhood technology in gas-powered vehicles. In just the past five years, the percentage of light- and medium-duty vehicles with VVT systems has skyrocketed from around 40 percent in 2015 to nearly 80 percent in 2020.

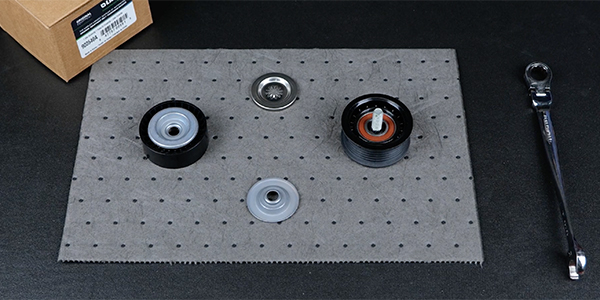

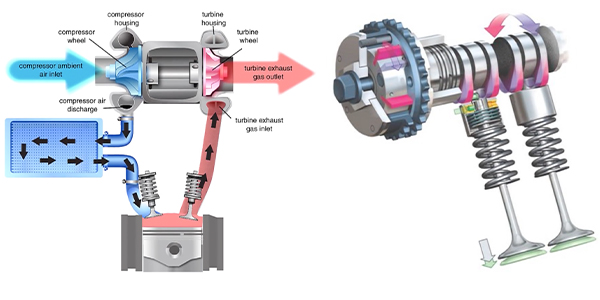

VVT actually alters the timing or duration of a valve lift event to improve performance, fuel economy and emissions. It’s controlled by a carefully integrated system of parts consisting of VVT solenoids, VVT actuators, an oil control valve and, yes, those cam phasers.

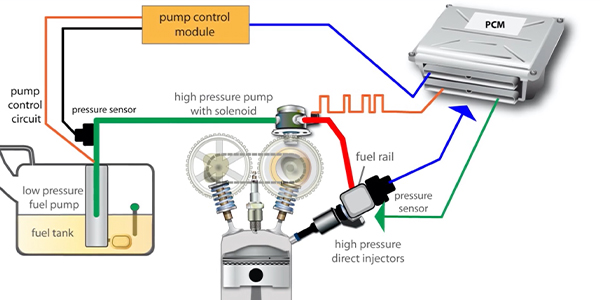

Here’s how it works: Phasing advances or retards the timing event by means of oil pressure and directed flow. The oil-control valve routes oil through a series of passages in the camshaft that force the hydraulic phaser to rotate back and forth in relation to the orientation of the camshaft. This rotation determines the amount of advance or retard of the cam, and therefore the valve timing. The oil-control valve contains the solenoid, which opens and closes internal passages in the valve’s body, changing the flow direction and rate as dictated by the PCM.

Just as with the engine itself, oil is critical to the VVT system – the leading cause of all VVT failures is oil contamination. The screens in the solenoids are smaller than the diameter of a human hair and can easily be clogged with sludge. The blockages of these oil passages can reduce oil flow and even limit the full travel of the cam phasers. In many cases, sludge and debris build up because of a lack of maintenance or using the wrong-viscosity oil. That’s why it’s critical that your customers follow the recommended service intervals for their vehicle, and that they ALWAYS use the oil viscosity that’s recommended by the manufacturer.

By 2025, it’s estimated that nearly all gasoline-powered vehicles will employ VVT technology so the repair opportunities will continue to increase. Luckily, many aftermarket companies continue to make significant improvements to the quality of the original OE designs. Use of these advanced components will help your customers’ cars live long and … well, you know.

This video is sponsored by The Group.