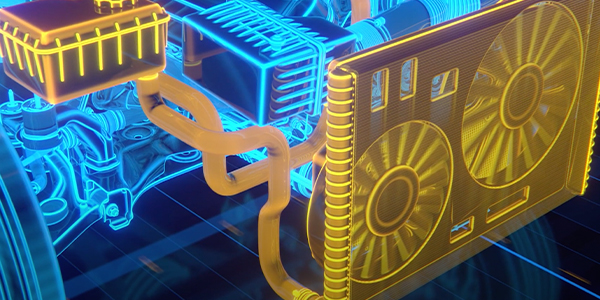

Today’s complicated cooling system no longer just keep the engine cool – they must cool AND warm various complicated components under the hood, as well as other areas of the vehicle. To do so quickly and efficiently, today’s vehicles use ‘modular’ coolant hoses.

They’re called that because hoses contain modules that may include a branching tee in the hose, quick-connect, valve, drain, air-bleeder or sensors. All have fluid flowing through them and are critical to the proper operation of the cooling system. They can be significantly more costly than standard, molded coolant hoses – so how can you help your customers be prepared?

Many years ago, the average vehicle had only four or five hoses including the upper and lower radiator, heater inlet and return, and a water pump bypass hose. In some cases, the lower radiator hose had a wire insert to keep it from collapsing at high engine speeds. Vehicles built during the past several decades may have a dozen or more small inside-diameter coolant hoses that perform diverse duties, like heating the throttle plate assembly or warming up thermostatic idle speed controls.

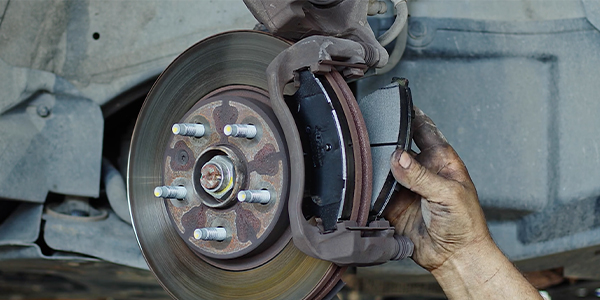

Determining a worn-out hose just isn’t as simple as it used to be. Typical rubber hoses generally wear from the inside out. You used to be able to do a simple “squeeze test” to check for a failing hose but now that’s a challenging chore, even with the hose removed from the vehicle.

Most often, hoses fail because the coolant carries an electrical charge from component to component. The hose, liquid coolant and the engine/radiator fittings form a galvanic cell or “battery.” Called electrochemical degradation, or ECD, this chemical reaction causes micro-cracks in the hose tube, allowing the coolant to attack and weaken the hose reinforcement. Failures result from internal striations or cracks in the hose rubber, leading to pinhole leaks or a burst hose. Gates hoses, for example, have been specially designed to be “ECR” or Electro-Chemical Resistant.

Other factors can damage hoses as well. Fluids, including oil and other petroleum-based products, attack the rubber compounds and softens the hose either externally or internally through contaminated coolant. An oil-contaminated hose will feel spongy and bulges or swelling will be present. External oil leakage onto hoses should be corrected immediately and the hoses should be replaced. If a petroleum product contaminant is found within the cooling system such as from a failed head gasket, it too should be repaired, and all coolant hoses replaced.

Don’t forget to check for heat and abrasion as well. Look at where the hoses are routed and protect the hose from heat sources, sharp objects and even original metal cradles that came with the vehicle from the manufacturer.

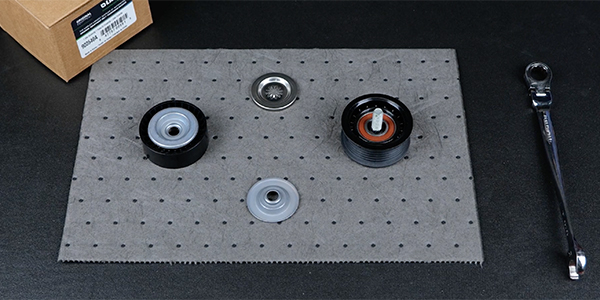

While standard, molded EPDM hoses typically fail around the 95,000-mile mark, modular hoses typically fail much earlier. The plastic utilized with the branching tees, quick-connects and other components are affected by the same conditions as the hose, particularly from heat, and will become brittle over time.

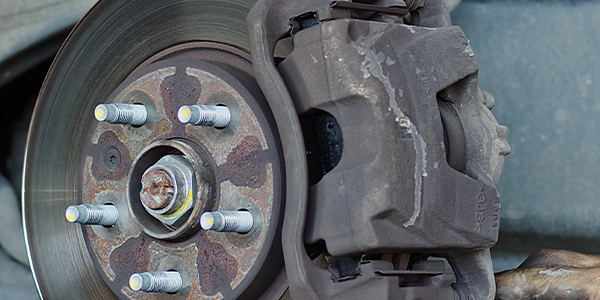

Coolant hose failures can lead to anything from a driver being stranded on the roadside to a significant and costly engine overhaul. Replacing these complicated components with the best products will keep your customers safe. Do them a favor by explaining why preventive maintenance is in their best interest.

Visit Gates Corporation for more customer service information.