Since the 2011 model year, all power window systems have been mandated to include anti-pinch technology. This technology measures the resistive force being applied by the electric window motor. This feature stops and reverses the window motor to prevent an occupant from being injured.

The resistive force can be measured in two ways by the anti-pinch system. First, the force can be measured by the amount of current being drawn by the motor. Second, the position and force can be measured using a hall effect sensor on the motor assembly. Most vehicles have one type of sensor. However, some vehicles will have two kinds of sensors.

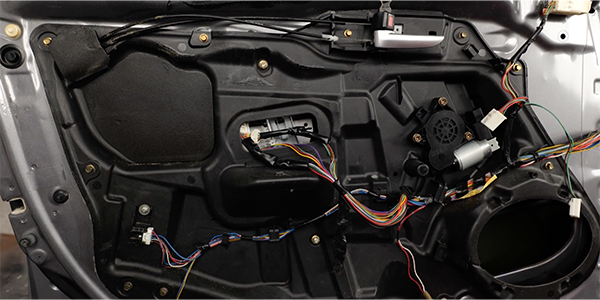

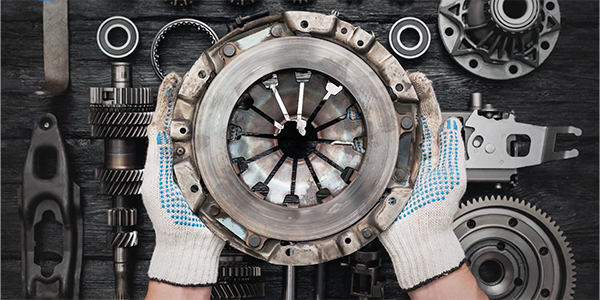

No matter how the force is measured, the condition of the window regulator, tracks, and the motor is critical for the anti-pinch system to work as intended and not cause a false activation.

You may get a customer at your shop complaining that the window reverses and returns to the fully open position when they try to close a window. Remember, the anti-pinch mechanism can’t distinguish between a finger and a damaged regulator. All the system know is that the motor is drawing more amp or the motor’s speed has dropped.

The root cause of the false activation could be ANY component that makes contact with the glass. It could be a damaged clip, regulator, cable or even layer of window tint. This is why it is essential to perform a complete inspection of the window components inside the door and the condition of track and weather stripping on the door’s exterior. Just one damaged component can increase the force to raise the window.

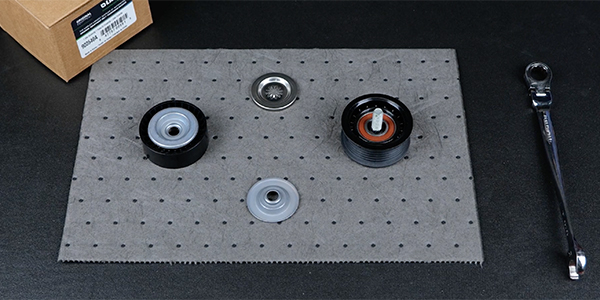

When replacing a window regulator or motor, look at the procedures in the service information. Another option is to scan this QR code on the side of the box for this Lemforder window regulator. The installation instructions can save you from removing unnecessary components or damaging trim pieces.

This video is sponsored by Lemförder.