have special techniques to retract the pistons and adjust the parking brake. Also, you don’t have to worry about wearing high-voltage protective gear to service the brakes.

What should you worry about? With these vehicles, the major aggravation for shops is brake noise. Why? It is not because they are of a bad design, it is because there is not an internal combustion engine to cover up noise.

On the 2021 Q4 e-tron, Audi decided to use drum brakes for the rear. Depending on motor output, the disks on the front wheels measure between 13.0 to 14.1 inches in diameter. In the rear, are drum brakes. Audi claims the drums have low wear and require little maintenance. Also, Audi claim drums reduce the risk of corrosion. This is because in a purely electric drive the rear wheel brakes are used only rarely in everyday driving.

Regenerative Braking

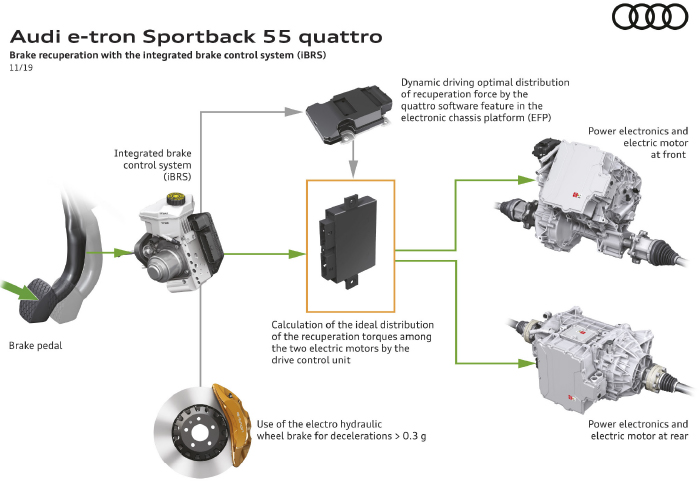

A hybrid or EV vehicle recharges its high-voltage battery through regenerative braking. With regenerative braking, instead of just wasting that energy by releasing it into the air as heat, the vehicle captures it and saves it in a box in the back of the car as stored energy. Later, that stored energy will be converted back into kinetic energy and poured back into the car’s operation.

Regenerative braking is an EV’s or hybrid’s first choice for braking. During regenerative braking, the brake pedal acts more as an interface for the ABS module than as a request for braking. The brake pedal and ABS module pressure sensors “tell” the modules of the hybrid system that a request for braking has been made and how much braking is desired.

The modules calculate the driver’s pedal efforts for the correct pedal feel and stopping power. The modules that control the hybrid system then apply regenerative braking via the motor that becomes a generator, as needed. More regenerative braking increases the amount of electrical charge generated for the battery. Brakes are applied to stop the vehicle from rolling at or near a stop. Some hybrid systems apply hydraulic brakes at lower speeds.

On most hybrids, the pressure generated for the calipers is not, under normal conditions, the direct result of the driver’s foot pedal efforts. Instead, the pedal-generated pressure is used to stimulate a pressure sensor in the system that makes up the brake request. Under emergency conditions and ABS corrections, most EVs and hybrids will use hydraulic brakes exclusively.

What is the service opportunity? Brake fluid flushing and bleeding are typically listed in the service schedule every two years. This is because not only is there an ABS hydraulic control unit but a brake pedal simulator. If the brake fluid is past its prime, it can damage these components.

Brake Noise

Electric vehicles and hybrids have a built-in disadvantage regarding brake noise. Since there is a quiet electric motor, brake noise will be more noticeable to the driver.

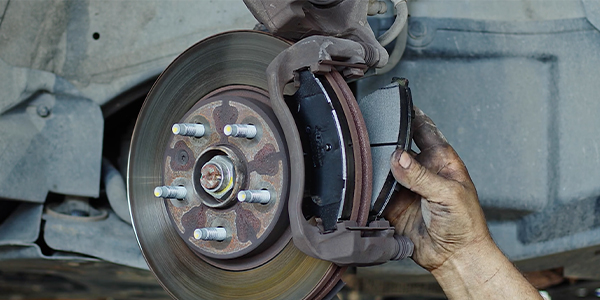

Noise typically comes from the areas where the pad makes contact with the caliper for several reasons. The noise may be induced when the caliper no longer applies consistent force to the brake pad’s surface that makes contact with the rotor.

The prime suspects of brake noise are typically the brake hardware and brake dust building up on the slides. The pad slides can become contaminated with corrosion and brake dust. Also, the pins that hold the pad in place can cause the pad to hang up in the caliper.

When replacing the pads, use a high-quality brake procedure and replace the hardware. For example, the anti-rattle clip and pins might look great after a few shots of brake cleaner, but they could be worn out and might not last the life of the new brake pads.

Another consideration when selecting brake pads is how the pads are protected against corrosion. Since the pads will likely be on the car for an extended period, corrosion can destroy the bond between the backing plate and friction material.

Brake Wear

Some e-tron models often get to 70,000 or 100,000 miles with the original set of pads because regenerative braking creates most of the braking force. But, in some rust belt states, the hardware, rubber seals/boots and calipers may fail before the pads wear to the minimum specifications.

When pads remain on the vehicle for a long time, there is always a risk of pad delamination due to rust jacking on the backing plates. Why? The majority of the time, the pads never reach conventional operating temperatures, which can cause corrosion between the backing plate and friction material because the pads never get the chance to dry out.

Since it’s impossible to perform a conventional break-in/bedding procedure on the test drive, ensure the manufacturer promises excellent performance right out of the box. Also, applying a non-direction finish with a ball hone will help the new pads evenly deposit a layer of friction material to the new rotor.

Service Tips

With many EVs and hybrids, the nuts and bolts for a brake job are the same as an internal combustion vehicle. The extra steps are typically required in the retraction of the caliper’s pistons and parking brake. Some of these vehicles might require a scan tool for other procedures.

In the case of Audi, simply pushing the brake piston back can cause a code for a hydraulic circuit. This is tripped when the pedal is first applied and sinks to the floor, just like on every vehicle. But, Audi uses pressure transducers on each hydraulic circuit. When the pedal is first depressed, the pressure readings do not match the pedal’s movement, so it sets a code. The good news is that the code might go away after one or two key cycles.

Another service tip is to pay attention to the keys. Many EVs and hybrids use proximity keys that unlock doors and wake up vehicle systems. Pay attention to the directions in the service information that might require you to turn off the vehicle by removing the keys from the bay before service.

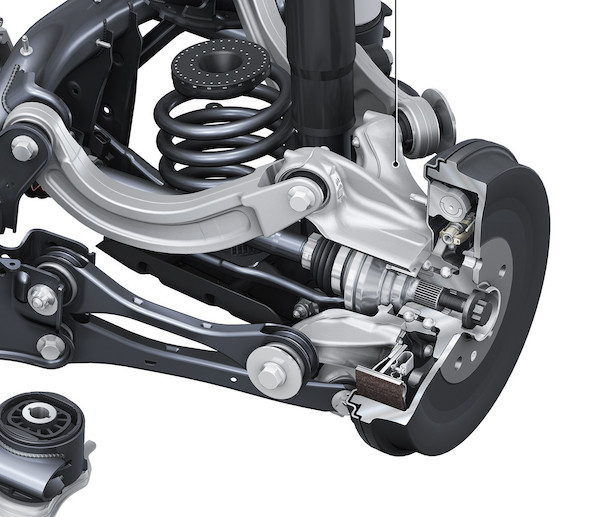

The most neglected item when servicing an EV or hybrid is a basic undercar inspection. These vehicles have suspension, drivetrain and steering components that need a periodic inspection. Do not miss these opportunities.