The fuel tank and pump are considered the lifeblood of a vehicle, supplying and circulating fuel to other critical components throughout the vehicle.

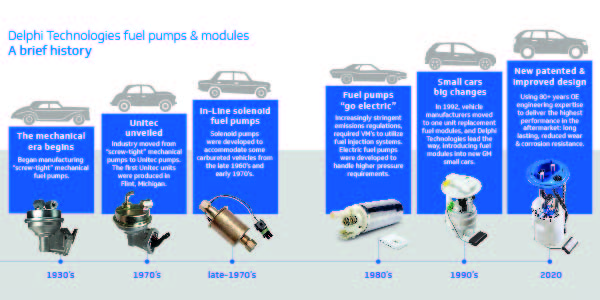

Delphi Technologies has been a manufacturer of fuel delivery parts for over 80 years, and a lot has changed since then.

With over 30 OE-proprietary innovations and 150 patents in fuel technologies and fuel management sales coverage at 95%, Delphi Technologies is proud to be one of the top suppliers in the aftermarket industry.

Delivering premium parts at every turn

As a Tier 1 supplier to the top 25 global vehicle manufacturers, our reputation is built on delivering high-quality parts. Here are just a few of the ways we ensure our parts are top-notch:

· All our products must meet or exceed OE-specifications

· A dimensional analysis is performed on each part to locate potential design improvements

Tested to endure the harshest conditions

All our components undergo also rigorous testing and are built to latest in the toughest scenarios. These are just a few of the tests we perform:

· Polarity Testing

· FLVV Leak (Safety) Testing

· Fuel Level Sensor Testing

· Automotive Fluid Compatibility (Contaminate Test)

· Performance Endurance Vibration Testing

Distinctly Delphi – Fuel Technology you can rely on

What makes our fuel technology so different?

· Anodized aluminum can reduce flow loss by up to 100% in severe contamination

· New carbon commutator extends pump life by up to 300% over copper by reducing oxidation and premature wear

· Over-molded armature protects pump windings in corrosive environments

· Button style contacts feature additional wear material that can last for over 1 million cycles

· High-capacity synthetic mesh can filter out all items larger than 30 microns

And when it comes to our fuel pumps, we also have a few unique features:

· Increased terminal size and enhanced connectors eliminate excessive electrical resistance, improve heat dissipation, and boost current outflow capacity

· High-durability noble metals fuel level sensor for improved long-term sensor integrity

What causes a fuel pump to fail?

Eventually, fuel pumps need to be replaced after about seven to ten years. However, if your fuel pump fails before this, there’s likely something that needs to be fixed. So, what are some of the common causes of premature failure?

· Running your vehicle near empty doesn’t keep the fuel pump fully submerged, which may cause the pump to overheat

· Extreme hot/cold environments

· Contamination in the fuel tank

Did you know that the warranty on your new pump may be voided if you don’t clean tank before replacement? Maintenance is one of the easiest ways to not only ensure optimized performance, but it can also greatly extend the life of both your fuel tank and pump.

Installing a new fuel pump in a dirty fuel tank can cause premature wear, or worse, a brand-new pump to fail completely. That’s because dirt, debris, and contamination in the fuel tank can clog the brand-new strainer, which was most likely the cause of the previous fuel pump failure.

We know it can be difficult to keep your fuel tank and pump clean—that’s why we’ve developed a solution to help!

Introducing the Fuel Tank Cleaning Tool

Even the toughest fuel pumps need to begin their life in a clean environment. Dropping the tank to perform maintenance can be both a timely and laborious task. Delphi’s recommended method to clean the tank is using a low-suds cleaning solution in combination with our Fuel Tank Cleaning Tool (FC02). This tool can help clean those hard-to-reach places inside the fuel tank in less than five minutes!

· Designed for use when removing the tank to clean and rinse (recommended) is too difficult

· Innovative design fits into any tank and swivels to clean corners

· Three rare earth magnets installed in the head—paired with fitted wipe—to help capture debris

· Five custom fit microfiber wipes

Check out our cleaning tool in action: https://youtu.be/I66xQhfSwYU

This Article is Sponsored By: Delphi