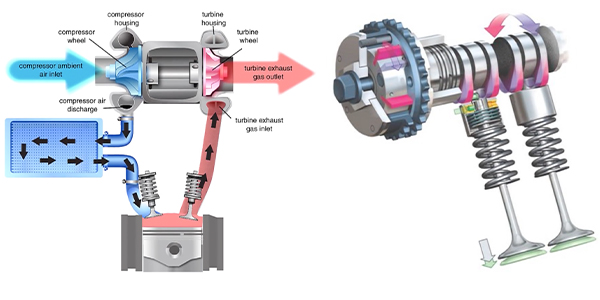

You already tell your customer how important oil is to their car’s valvetrain, turbocharger and overall fuel economy – but did you know that oil plays a vital role in a vehicle’s A/C system as well? With operating pressures up to several hundred pounds per square inch and operating temperatures of several hundred degrees, compressors need plenty of lubrication and the correct oil to survive in these harsh conditions.

No, it’s not engine oil but it’s important for the entire system to be free of acids, contaminants and sludge, because they can cause a number of problems in the system. Those duties are managed by the right compressor oil.

In older systems, refrigerant-charged oil circulates through the A/C system, although the system maintains a certain percentage of oil in the compressor at all times. This lubrication performs two important functions: It reduces friction between metal parts, which keeps heat in check; and it minimizes wear from metal particles that can cause premature compressor failure and clog condenser passages.

In newer A/C systems the oil stays in the compressor and doesn’t circulate through the entire system. That’s why it’s so important to refer to the oil-amount specifications for that vehicle.

Burnt oil in the system is never a good thing so if your service recommendations call for replacing a failed compressor, your team should always drain the oil from the old compressor – the oil can tell you a lot about what happened

Compressor oil should look clean – if it’s contaminated with iron particles, it indicates that the system suffered from “Black Death.” Yes, it’s just as awful as it sounds. Black Death happens when moisture enters the system and reacts with the refrigerant and oil to form acids and sludge, which can clog the system or damage the compressor.

You can help prevent Black Death by following the recommended service intervals and service procedures for flushing the A/C system. Cutting corners by not evacuating the system for the full time recommended and leaving flush in the system can break down the oil and damage the compressor. Flushing the system is always recommended when you’re replacing a compressor, unless the A/C system uses a parallel-flow condenser. In that case, you’re going to need to remove the condenser and replace it with a new one

You also want to be careful with leak-detection dyes on later-model compressors. Many late-model compressors have a much lower oil capacity, four ounces or less, making the system more sensitive to additives. Because of their design, some compressors will treat dye like oil, which may overcharge the compressor. Using sealants can have the same effect. In fact, you should never use sealants in later-model compressors, because they’re designed to react with air, and air in an A/C system will clog the passages.

It’s also imperative to use the correct oil. Hybrid scroll compressors, for example, like you might find on a Toyota Prius, require a specific type of oil with high die-electric properties. Using Polyalkylene Glycol or PAG oil on a hybrid compressor will cause the unit to fail and serious damage to the electrical system.

Finally, using a lubricant enhancer can help extend compressor life and improve system performance. A product such as this one chemically creates a “boundary film” on the internal surfaces of the A/C system, keeping acids and corrosion caused by moisture away from the metal parts, which reduces friction and metal wear.

Note: gpd 65 series compressors (e.g., 6511414) are prefilled with the correct amount of oil specified for the system. Replacement compressor design and oil requirement may vary from original design. Refer to manufacturer specifications for vehicle and replacement compressor.

Your customers only worry about their vehicle’s air conditioning once: when it doesn’t work. With your help, they’ll worry even less.

This video is sponsored by The Group Training Academy.