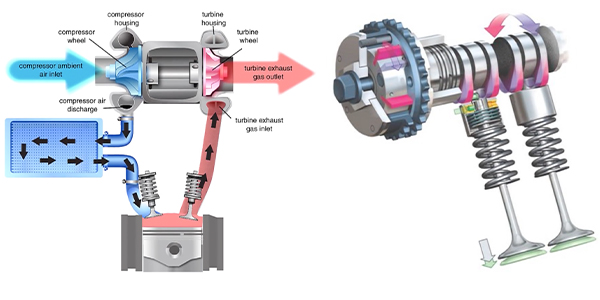

As a shop owner, it’s important for your team AND you to understand how catalytic converters work, what triggers a catalyst inefficiency code, what causes thermal damage, and catalyst poisoning and how those problems reduce the efficiency of our catalytic converter. In this video we will discuss some diagnostic procedures for catalytic converter problems arising from issues relating to air, in our air, fuel and, spark conceptual grouping

Our first step is to do a visual inspection for worn out gaskets and vacuum leaks. Do a smoke or soap bubble test if you suspect vacuum leak but cant find it

Check your mass air flow sensor and clean or replace as needed (use a scan tool or multimeter to note quick increase from 2-7 grams per second at idle to 15-25 g/s at 2500 RPM)

Test and replace any lazy upstream oxygen or “Air/Fuel” sensors– a recent CARB emissions roadside emissions check found that half of all converter failures were due to a lazy upstream sensor.

- Check upstream O2/AF sensor is not lazy, weak, or fouled.

- Voltage should rise to 850 mV

- Voltage should drop to 150mV

- Never drop below 0

- Voltage should switch once every 2 seconds to 5 times per second

- Voltage rise time less than 80 ms

- Voltage fall time should be less than 100 ms

Check upstream AF sensor

- Add metered propane, or something highly combustible like brake cleaner into air intake to force it rich, or force a lean condition with vacuum leak downstream from MAF. In both cases you should see the sensor respond very quickly. If a sensor is lazy, it should be replaced immediately.

- 02 and Air fuel sensors should be replaced as part of your regular maintenance and tune up schedule.

Look for and patch exhaust leaks. Common locations for exhaust leaks are near hangers, at gaskets and where two surfaces are welded together. Exhaust leaks can result in a lean air fuel mixture.

Check engine compression to make sure the pressure in combustion chamber is within spec and evenly balanced across cylinders.

This video is sponsored by AP Emissions Technologies.