CC:

Your customer comes in with a misfire or other drivability concern. With today’s complex vehicles, diagnosing the problem may make you, your service advisor and your technicians more than a little uneasy. Well, whether the vehicle is showing a trouble code or not, the good news is there are only four possibilities you need to consider.

Admittedly, when you find yourself dealing with an engine drivability or performance issue, finding and isolating the cause can seem a bit daunting. But there are really only four fundamental areas that could cause such a problem.

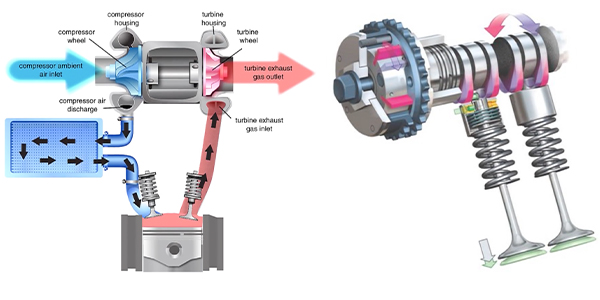

First, the engine’s mechanical condition and specifically its ability to compress the air charge and seal the combustion chamber.

Second, the engine’s volumetric efficiency – really, its ability to breathe – encompasses any condition that prevents air getting in and out of the cylinders.

Third, the question of igniting the fuel. In the case of a gasoline engine, of course, this includes anything that prevents a strong spark at the right time.

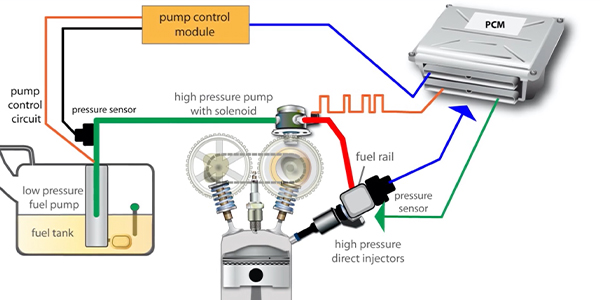

Fourth, consider the fuel. This doesn’t only mean the condition of the fuel, winter fuel or summer fuel, but also fuel delivery and proper fuel mixture delivered cleanly and at the right time through the injectors into the combustion chamber.

Engine misfires are nothing to ignore. Whether there’s a DTC set and the check engine light is on or it’s just something you can feel, misfires are dangerous. Not only will they reduce fuel economy and increase emissions, they can cause serious damage to engine components and the catalytic converter.

What do you do? Start by checking the canary in the coal mine – in this case, the engine control module, or ECM. That’s what turned on the check engine light in the first place. Of course, it’s not always as simple as plugging in a scanner and getting a solution. You need to take the time to understand the code and the systems you’re working on because even the most routine tasks, like changing a battery, often require very specific processes be completed before the job is done righ. If you do your homework, your time spent testing and repairing will be better utilized and your diagnoses will be more accurate and efficient.

The best way to proceed is to follow a logical diagnostic process, one that you apply to every troubleshooting situation that rolls through your door. When you follow the same process every time, it removes many variables you are likely to face when you’re trying to isolate and find the cause of your customer’s concern.

A standard set of steps will not only make you more accurate, it will help make your diagnostic process quicker and more efficient. If you follow the same process, you won’t make the mistake of automatically ignoring a system or component that you just KNOW can’t be part of the problem.

Remember, the vehicles you are seeing in your shop today are more complex and integrated than ever. You can’t get away with “kinda close” anymore. You either get it right or you get it wrong. And if you get it wrong, your customers will not be happy – they’ll either be back or they won’t. Either way, it’s bad news.

For more information about ECMs and systems, visit Cardone.com.

This video is sponsored by The Group Training Academy