Back in 1988, the BMW 7-Series put the first nail in the coffin of the mechanical throttle cable. By 1997, Chevrolet introduced its “throttle actuator control” (or TAC) on the new C5 Corvette.

Today, the old throttle cable is almost nothing more than a memory. Virtually every vehicle manufacturer has an electronic throttle system on every make and model.

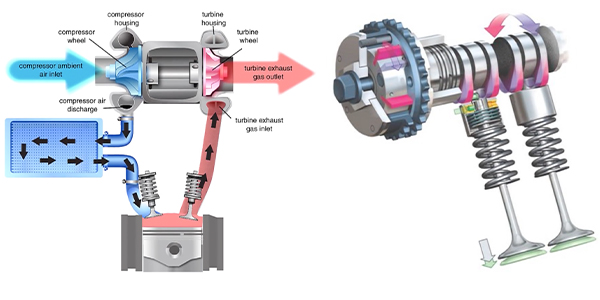

Most throttle bodies have two wires that control the throttle body motor function, more similar in fact to the control of a power window motor than then old mechanical throttle cable. To drive the throttle blade open, power will be supplied on one wire while the other wire is supplied ground. In order to close the throttle blade, the polarities will be reversed.

However, your customers probably don’t know this – nor, really, do they need to. They count on you to make sure their car goes when it needs to.

The throttle body also incorporates the multiple Throttle Position Sensors. These are similar to the APP sensors in the way that multiple sensors are used for safety and each sensor operates independent of the other sensors.

When attempting to diagnose an Electronic Throttle Control fault, it is important the technician follow Diagnostic Trouble Codes carefully, always check Technical Service Bulletins and look for software updates. Many times, the DTC will be divided into three areas: APP, logic (PCM or wiring), or throttle body (TPS)

Electronic throttle control (ETC) has been responsible for improving fuel economy, reducing emissions, protecting powertrain components and providing a better overall driving experience.

Regardless of the vehicle, electronic throttle controls typically involve two different components: the accelerator pedal position sensor (APP) and the powertrain control module (PCM) that control the electronic throttle body.

In most applications, the APP replaces the throttle cable that connected the acclerator pedal and the throttle blade. Instead, the APP has two or more sensors that act as an input devide to the vehicle’s PCM or, in some cases, the ETC standalone module. In many cases, the APP incorporates a calibrated spring assembly so the driver has a familiar feel when pressing the accelerator pedal.

The throttle body does the actual work but because of the complexity of the system, faults can occur. These faults can be frustrating for the motorist, the service advisor and the technician because even if an intermittent fault happens for just an instant, it may result in a “limp-in” condition for the customer.

Some of the concerns customers with ETC system faults may have can include inoperative cruise control, vehicle stuck in limp-in mode or illuminated warning lights.

Here’s a caveat: It is also important for your technician to remember that other areas of the vehicle’s control system may cause throttle-related problems that aren’t necessarily caused by the electronic throttle control system. Faults such as wheel speed sensors could affect throttle opening and should be diagnosed first. It’s a fact – electronic throttle bodies have high OE Failure rates. When the original fails it affects a vehicle’s power, fuel economy and drivability. Make sure you restore the your customer’s confidence and satisfaction by recommending with a high quality product that matches OE for fit, form and function like the ones offered by Standard.

This video is sponsored by The Group Training Academy.