Your customers may look under their hood and be overwhelmed by the wires, plugs, sensors and components staring back at them – they come to you for explanations and answers to why their vehicles aren’t starting or running correctly.

The components in a gasoline powertrain include spark plugs and ignition coils, of course, but also include fuel pumps and injectors, electronic throttle bodies and a wide assortment of sensors, including manifold pressure and Mass Air Flow sensors, knock sensors, cam and crankshaft position sensors, oxygen sensors and pressure and temperature sensors.

It’s a complex dance that all these components need to perform in order for a car to reach its peak efficiency – in fact, components that are out of spec can prevent your customer’s vehicle from starting in the first place.

Today’s state of the art ignition coils feature both high dielectric strength and superior temperature and vibration resistance. Coils are designed for specific applications, and some of the newest technology includes pencil ignition coils that feature primary current control and diagnostic functions.

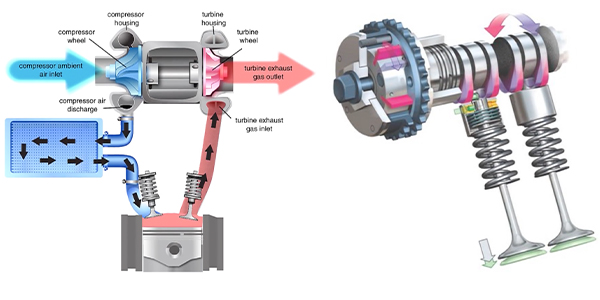

Once the engine has started, fuel must continue to be ignited in a precise manner. Today’s fuel injection technology puts the fuel where it needs to be when it needs to be there. Optimum spray patterns give perfect mixture generation and efficient combustion, resulting in dependable performance and low consumption and emissions.

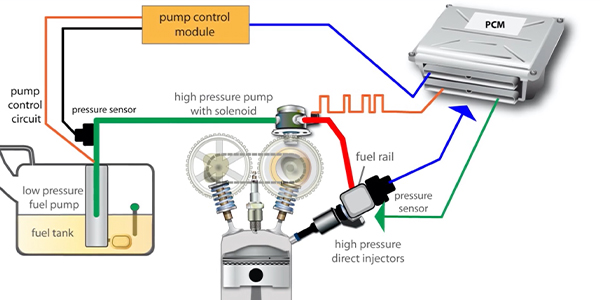

Port fuel injectors are located in the manifold and deliver fuel to the intake port to create an ideal air/fuel mixture to power a vehicle. GDI injectors are positioned directly in the cylinder, where fuel is sprayed at carefully calculated pressures. Today’s direct injection systems use a high pressure pump under the hood that optimizes performance from 65 psi to 2900 psi at flow rates up to 1.12 cubic feet per minute.

Further back in the system, a turbine pump mounted in the fuel tank virtually eliminates fuel pulsation and noise, providing exceptional hot-start performance and preventing on-board electronic interference, thanks to superior electronic shielding.

And of course, getting the engine started and keeping it running is handled by a staggering variety of engine management sensors under the hood. These sensors provide safety, convenience and accessibility features that yesterday’s cars just couldn’t address, along with improved power, efficiency and reliability. Customers demand more from their vehicles, so the vehicles depend on more sensors than ever – even the most compact-class vehicle is likely to have more than 60 different sensors on board. These components are actually wear components, so you’ll likely need to explain what a sensor does and why it’s important.

Your customers will likely be overwhelmed by their engine management systems – thanks to trusted aftermarket partners you can help make diagnosis and repair easy and reliable.

This video is presented by The Group Training Academy.