By Bob Cooper

If you speak with most shop owners, they’ll tell you that they think their shop is worth "X" amount of money. Ask them how they came up with that number, and they’ll tell you it’s based on what they heard another shop sold for, or it’s predicated on their annual sales. But, if you really want to know what your shop is worth, first of all, forget everything you’ve heard about “goodwill” and the fact that you have thousands of names in your database. That’s icing on the cake, but it’s not something a buyer can take to the bank. And although there is some value associated with some franchise names, there are two things that are most important to a buyer: the “tangible assets” and the “income history.”

Tangible assets are things like real estate, cash in the bank, secured receivables, inventory and equipment. To put it another way, these are the assets that buyers could turn into cash if they had to. When you’re establishing the value of your inventory and equipment, bear in mind that the actual appraised value may very well be far less than what you originally paid. So tangible assets are always number one. In regard to “income history”, we all know that past performance is no guarantee of future performance, yet the substantiated income history of a company is what buyers can use to forecast earnings. And don’t forget: The amount of money the “company” made does not include any income you’ve drawn out of the company as a salary. The company’s income is the amount remaining after all expenses, including your salary, have been considered. So imagine you’re looking to buy a shop, and let’s say the tangible assets are worth $400,000. In addition, let’s say the shop has a history of generating $100,000 in annual income after all expenses, and let’s say the owner has been drawing a salary of $80,000. So if you were to buy that shop, how much would you be willing to invest? Well, only you can answer that question, but I hope you take these 6 points into consideration:

1. If you were to liquidate after you purchased, how much could you sell the assets for? I call this the “street value” of assets.

2. How long has the company been in business, how long have the key employees been with the business, and what’s the probability that these key employees will stay on once you buy?

3. What is the probability of the company continuing to earn the same $100,000 in annual profits, and for how long?

4. In regard to the $80,000 salary the owner was taking, would you be willing to do what he or she does for the company for the same amount? Or will you be able to hire someone to do that job for the same or less?

5. If you were to invest the same amount of money in any other business or investment vehicle, would you receive a better return?

6. What are the terms of the purchase price? You may be better off to pay a higher price in return for a lower down payment, good financing rates and a non-compete.

So, how do you establish the value of your business? Not by the icing (goodwill and number of names in your database), but by looking at it through the eyes of both a banker and a buyer.

For help building a more successful auto repair business, learn more about the 1-on-1 coaching and customized action plan offered through the Elite Coaching Program.

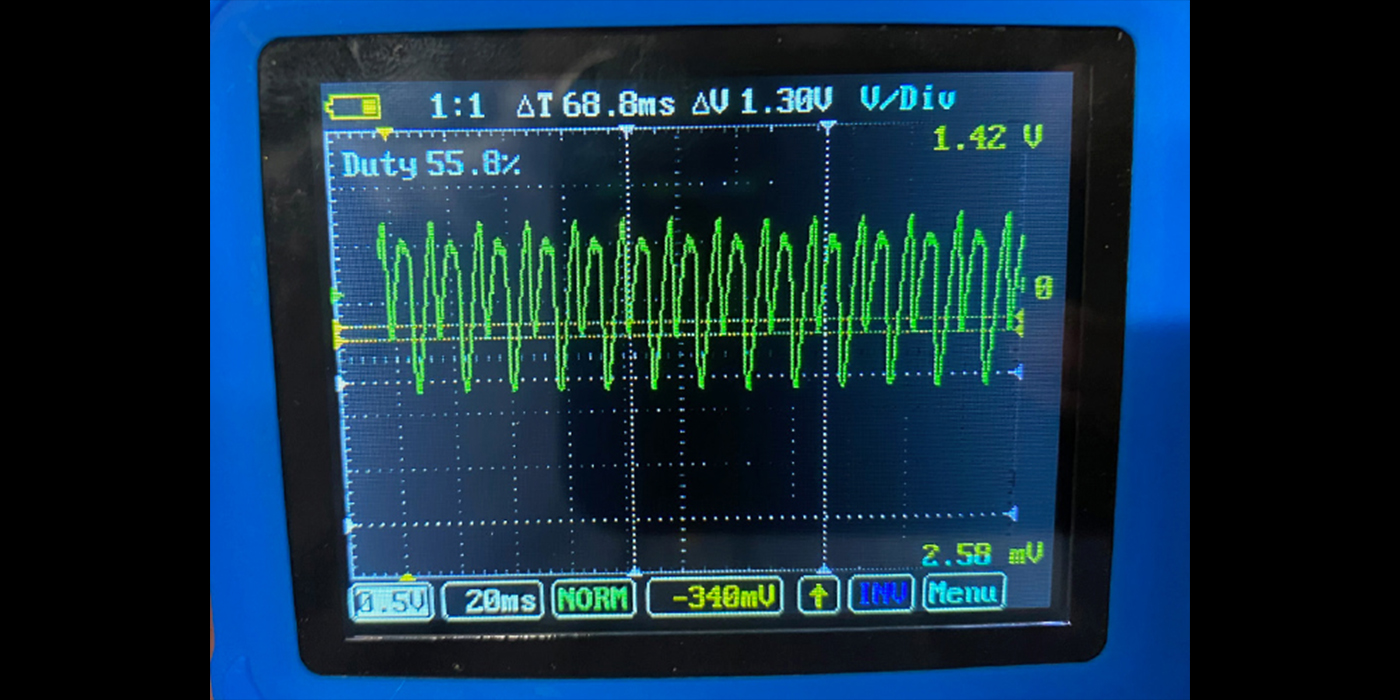

I’m not a financial scholar by any means, but I know what return on investment (ROI) is. It’s a mathematical formula that yields a representation of the profitability of any type of investment. In the automotive repair industry, we primarily associate this with equipment. Admittedly, I’ve never used the term much, more often approaching things from the standpoint, “Am I making money with this or not?” As technicians and shops, our typical thought process centers on each individual job, how much time and money we have into it, so we’re used to thinking profit or loss, and also pretty good at knowing if we made money, or if we lost our “back quarters.”But over time I’ve learned that the thought process alone is not always the best approach, and making money doesn’t necessarily mean a good ROI. Even if you don’t go crazy with an exponentially long, complicated equation, if you understand the basic idea and process of calculating ROI, it can help you make good purchasing decisions. The base calculation would be dividing your net profits by the cost of the equipment. That’s your ROI. Then, if you want to take it further, you can divide that number to get a time-based ROI average.Let’s look at a basic calculation. You buy something for $10, then sell it for $14. Your profit is $4. Divide profit by investment, ($4/$10) and you get an ROI of 40%. Not bad, but if it took two years to make this profit, then your ROI would be 20% annualized, which is not as impressive. You can use this basic formula to compare products you sell as well, and it may help you decide what’s best to keep in stock or not.Now let’s try something with equipment. You have an old tire machine that’s paid for. You average one set of tires per week and it takes 1.5 hours to complete the job. You decide to buy a new tire machine that is much quicker and more efficient but it cost you $20,000. Now the same job only takes one hour. Based on the cost of technician salary, you calculate that it saves you $30 per job with this new equipment. In this case you would use the formula: savings (additional profit)/investment. At one set of tires per week, that works out to $1,560 per year. $1,560/$20,000 equals an ROI of approximately 8%. That’s not too good. It will take you almost 12 years to pay off the new machine.On the other hand, if you average five sets of tires per week, then your additional profit for the first year is $7,800. $7,800/$20,000 equals an ROI of 39%. That’s pretty good. A general rule of thumb is to pay off any piece of equipment within two to three years. This puts you right on track.But now, here is the problem. This is where we throw the proverbial wrench into the plans. Equipment is tricky. You should also calculate in installation and maintenance costs, as well as the cost of training for the new equipment, and factor in how long the equipment is going to be relevant. This is an especially important factor when considering a scan tool, the required updates and how long before it’s potentially obsolete. In the case of a tire machine, you can also calculate in savings from other benefits of a new machine, such as no more damage to wheels or tire pressure monitoring system (TPMS) sensors, which the new machine can eliminate.Some of this can be overwhelming, and it makes me realize why it’s easier just to fly by the seat of your pants and wonder, “Am I making money or not?” It’s an important business aspect, however, to know what is behind the idea because it can benefit you in so many ways. Even without math, you can almost visualize the numbers in your head.I’ll try it by leaving the formulas out to decide whether it makes sense to buy a dedicated TPMS tool when you already have a full-function scan tool with TPMS ability.If you get a TPMS problem every day and you use your full-function scan tool to diagnose it, most likely it takes much longer to boot and longer to navigate to the function. Even then, it may not cover all you need. Because there’s such a vast amount of information that a full-function scan tool has, it simply takes more for the manufacturer to keep everything current. Plus, you often must still rely on service information for certain procedures and then, if it’s the only scan tool for your shop, it ties it up for use in other diagnostics.Now, let’s compare that to a dedicated TPMS tool. Built with only one function in mind, they can make the process much quicker, have greater coverage, boot quicker and quickly walk you through all steps of any required TPMS resets. When you factor in the savings in time and the fact that your primary scan tool isn’t tied up, you can prove the value of a dedicated TPMS tool through ROI calculations. On the other hand, if you rarely work on TPMS systems, you can prove it wouldn’t make sense at all, since you do have the function on your primary scan tool.While you haven’t done any calculations, you’ve thought of it in that manner and can picture where the calculations might end up. If you’re on the fence, the math will give you the answer. Ultimately, your accountant could take the idea even further, with an undoubtedly more advanced knowledge of ROI, and almost certainly a way to calculate depreciation into the formula. That’s where I sign off, but you get the idea. It’s a great concept that represents fundamental business financials.