The first step to increasing productivity in many shops is the introduction of Digital Inspections and Shop Workflow Worksheets on tablet devices that help to eliminate or minimize the use of paper in the shop.

The first step to increasing productivity in many shops is the introduction of Digital Inspections and Shop Workflow Worksheets on tablet devices that help to eliminate or minimize the use of paper in the shop.

A perfect example of this is NAPA AutoCare Center Craig’s Car Care in Allen, TX, whose owner shared with us that they save at least $1,200 a year on paper and ink cartridges alone.

A combination of professional-quality inspection reports, in conjunction with educational videos and detailed information about the service, make it much easier for the service adviser to guide the motorist to the right decision regarding necessary vehicle repairs. These easy steps can boost the average repair order to unprecedented levels, and technicians like the higher productivity levels because it puts more money in their pockets.

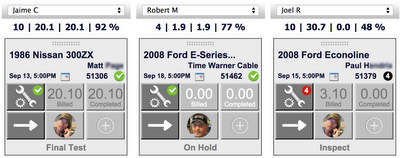

Even the paper rack can be eliminated and replaced by touch screens or big TV screens that show the entire shop workflow by displaying each vehicle in its current stage of repair (e.g., Inspect, Waiting on Approval, etc.). Additional details about technicians’ billable hours can be contrasted with completed hours and their time budget, so technician availability for new jobs is determined in seconds. This gives shop owners and service advisers the ability to take decisive action because critical information is available at their fingertips and updated in real-time. Figure 1 illustrates how easy the information can be digested.

In this example, vehicles are processed along the shop specific workflow, and we are able to measure a few key performance indicators with impressive initial results. These results are impressive because only a few data points can tell a powerful story. Established habits are identified easily and positive workflow change can be implemented and monitored.

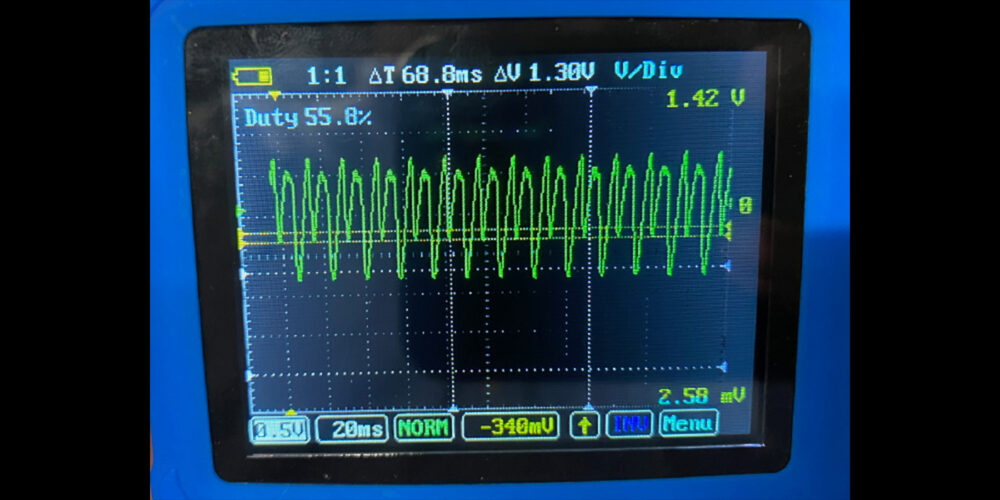

Check out the report snippet in Figure 2 that shows where process improvements can be made.

1. The first column captures the time the workflow step was entered.

2. The second column lists the workflow step.

3. The third column shows the work order value at the beginning of the workflow step.

4. The fourth column displays the amount of time that the vehicle stayed in the workflow step.

This is a pretty standard workflow at first glance. The only exception is that while work is being performed, an additional authorization by the motorist was detected.

Let’s review the details. The initial work order was worth $181, including the inspection that took two hours. Under standard conditions, a job worth $181 shouldn’t take that long, so it’s worth finding out if it was a longer “diagnose and test job” with a road test included. (Our technician efficiency report would be listing the details, but in the interest of our focus on the workflow, this topic is not discussed in this article.)

Despite the inspection delay, the service adviser did a great job of guiding the motorist to authorize additional work in the amount of approximately $1,200. The use of digital inspection reports and images, combined with the technician’s notes, contributed to that process in a big way.

Let’s now look at the two most time-consuming repair-related steps besides working on the vehicle.

Waiting on approval is no small feat (See A. Waiting on Approval). It was either really hard to reach the customer or the service adviser has simply put this work order on the back burner. As you can see, this created a chain reaction:

It was late during the day, so the parts couldn’t be delivered in time for same-day delivery (See B. Waiting for Parts) and the motorist had to wait one more day.

This is unfortunate, since only a few small changes in policies and execution as part of a review with the service adviser could yield significant improvements.

Assuming this report isn’t an outlier, the following best practices will improve the overall shop productivity:

• Make reaching the motorist a priority over all other activities.

• Find out the best way to reach the motorist at vehicle dropoff. The service adviser should ask for the best way to reach the motorist and record that phone number. In addition, he or she should ask about the possibility of text messages or email alerts to have alternate means of reaching the customer.

• Make vehicle repair the motorist’s priority. Do so by developing a script with the service adviser on how to politely, but firmly, create urgency while talking with the customer over the phone.

Figure 2 also displays a brief time period between finished work and vehicle pickup (See C. Pickup). The phone call for additional authorization, which was declined, has been used to notify the customer that the vehicle is ready for pickup.

While it’s a small report with just a few numbers, it gives you great insight to help you run the shop more efficiently. Additional reports that give you the important details to run your shop more effectively, even remotely from wherever you are, include:

• Technician efficiency (how long does a job take to be finished by tech and vehicle type?);

• Technician effectiveness (identify sweet spots technicians have when inspecting the vehicle, including the detection of pencil whipping and over-recommending); and,

• Shop effectiveness (how many and which technician recommendations make it to the estimate; how many canned jobs are used; estimate value vs. invoice value, etc.).

Reports like these provide enough detailed insight so that you don’t need to be in the shop all the time in order to know which positive changes to implement to make your business run more efficiently and profitably.