Time flies and here we are again with an update of our mission to make the back shop completely paperless. Of course we save trees by doing this, but the most exciting benefits are about boosting technician productivity, freeing up the service advisor from doing busy work and focusing on educating the motorist.

Customers are impressed by the professional look of the results presented at the counter or electronically and, believe it or not, would like to be educated by learning more about the inspection results. The next step is obvious: Technician worksheets and inspection sheets are now combined and available on a tablet, which is the newest tool to be added to the tech’s toolbox. The tablet is not only replacing paper, it also has the potential to replace computers at fixed locations in the back shop.

I welcome your thoughts at on how you would like to take the next step. Provide your comments at www.AutoVitals.com/EIS_Benefits.

Step #1 – Fast Finger Action Replaces the Car-Doctor Scribble and Even Typing.

This step is all about leveraging the digital world.

• One paper sheet can hold only so much. And most shops try hard to fit everything onto one page to simplify logistics and processes. So in order to accommodate all possible scenarios, the digital world offers plenty of space (infinite space, so to speak) for the tech to leave notes, and scribbling is replaced quick tapping — and they’re done.

• A picture speaks more than a thousand words. Especially when the motorist is eager to learn what exactly is wrong with his/her vehicle. Of course, one can take photos of the problem area with a smartphone or a camera, upload it somewhere and then attach it to an e-mail to be printed out. Or, one could simply press a button on the tablet and take the picture. Done.

• Voice recordings, taken with Siri or its Android equivalent, turn spoken notes into text or one can simply record voice notes to which the service advisor can listen. They are very useful, especially when complex repair situations are to be mastered.

• The service advisor traditionally shows the paper documents to motorists (“pardon the smudges, we are a repair shop and not a pharmacy”), or enters them into the shop management software (SMS) before showing the inspection results as part of the estimate.

Digital inspections, on the other hand, can be modified by the service advisor, augmented with embedded images, and, even better, different configuration settings on how the inspection results are sent to the service advisor can save tons of time. How, you ask? Imagine the actions recommended by the tech are canned jobs already known to the SMS. Certain SMS can support entering job IDs instead of navigating through a jungle of menu items when building the estimate. The estimate is built in less than 30% of the time needed for the manual approach.

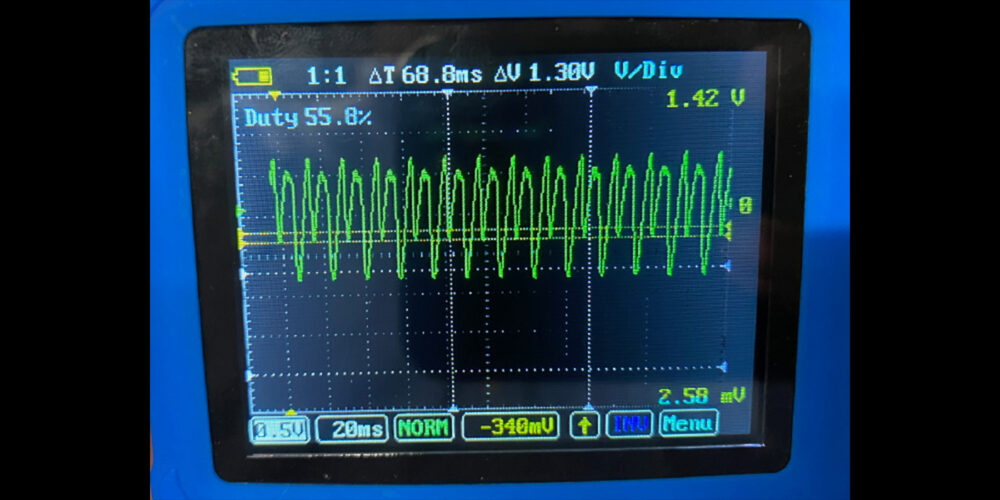

• Last, but not least, the electronic inspection sheet is built in such a way that the tech’s habit doesn’t need to change much. You can see how easy its operation is in the below image. One tap sets the topic to “Inspected and Passed.”This is an easy process and there are still measures built in to avoid “pencil-whipping.”

Step #2 – Bring OEM and SMS Knowledge to the Table(t).

Integrating with your SMS and an OEM catalog of service recommendations adds the next category of benefits.

• As mentioned earlier, canned jobs configured as a recommended action create one baseline for techs and service advisors alike. Reports for the shop owner allow unprecedented insight into how well techs and service advisor(s) work together to create a profitable shop operation, way beyond what today’s SMS is able to do.

• Mining the data of the SMS database allows you to detect jobs and parts, which are performed and ordered very often for the same vehicle type and can be proposed to the tech. The tech can learn from more experienced techs or simply confirm the proposal and adjust work hours when needed. The service advisor then confirms or adjusts the tech’s proposal.

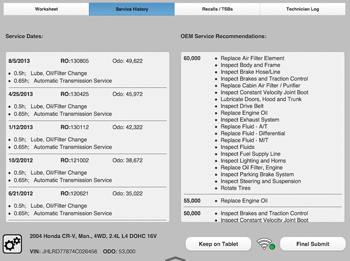

• Bringing the vehicle service history next to the OEM service recommendation on one page allows the tech to compare data quickly and select the recommended services by tapping the set of jobs or individual services. The image on page 9 illustrates how easy of a comparison those two sets of data can be.

• Recalls and TSBs can be looked up and selected for the service advisor to recommend to the motorist.

Step #3 – Replace the Technician’s Paper Worksheet

Step #3 – Replace the Technician’s Paper Worksheet

What if the tech doesn’t need to carry the technician worksheet around? What if the service advisor only needs to create the work order and assigns it to the tech in the SMS and, a few moments later, both the worksheet and the inspection sheet(s) show up with the vehicle designation on the tech’s tablet?

Welcome to AutoVitals Paperless Backshop service. It combines inspection and worksheet into one application on the tablet. Time clocking is made super easy, voice notes and images can be taken, the charged hours can be monitored and, last but not least, the tech’s individual efficiency score is visible and compared with the shop’s or even to the AutoVitals network’s best score. Check out the screenshot above and go to the Apple App store or Google Play to start your first inspection with the AutoVitals Paperless Backshop Application today.

Uwe Kleinschmidt is the CEO and founder of AutoVitals in Santa Barbara, CA. The company’s Web-based services focus on the independent automotive repair industry. AutoVitals’ products facilitate highly effective Concierge Auto Repair services, covering all aspects of the service advisor’s interaction with prospective and existing customers. Highly effective and optimized websites, workflow support in the shop, as well as customer retention and social media services are just a few ingredients. He can be reached by visiting www.autovitals.com or calling 1-866-949-2848.