During the 1920s, the term "model year" gained currency in the automotive industry. Auto execs determined to increase sales by annually introducing new automobiles to a motoring public hungry for the prestige of owning the latest motor vehicle technology.

Because the operative word in "model year" is "change," an outside observer would assume that the words "change" and "training" would go hand-in-hand in an industry that defines itself according to model-year improvements.

Equipment, training and information costs are rising dramatically for any shop wishing to remain at the leading edge of automotive technology. Despite the fact the electronics content of the modern motor vehicle is rising from about 15% on current vehicles to about 50% on vehicles entering the service market and, despite the fact the improved hybrids and other high-tech vehicle platforms will be arriving in showrooms this fall, the word “training” remains little more than a convenient buzzword in the vocabulary of most shop owners.

What Is Training?

Quite frankly, I’m biased against using the word “training” to describe the learning process that’s required to maintain technical competency in repairing today’s automotive technology. One definition of training might be to “make or become prepared or skilled.” While that definition covers teaching specific skill sets, it doesn’t describe the overall education process needed to become a modern technician.

A modern ASE-Certified Master Automobile Technician with the L-1 Advanced Engine Performance certification must be thoroughly familiar, not only with the hands-on skills required to replace various components, but also with the science and technology that makes those parts network with the concerted whole.

To illustrate, a fuel pump might be networked with the seat belt module as part of a safety fuel shut-off feature.

That feature might cause the engine to stall intermittently on some high-end European vehicles. While the operations involved in replacing the seat belt module is a skill set requiring “training,” understanding how a defective logic chip in a seat belt safety module can potentially cause an engine stall is a logical and critical thinking skill requiring a much broader-based “education.”

With that said, three types of training are generally available to independent shops. The first is product training that provides information for the selection, application and installation of a product. The second is training that provides for repairing complex mechanical systems like engines and transmissions. The last is electronics diagnostics, which is offered at basic and advanced levels.

Basic levels might be those offered in vocational training programs, while advanced levels are usually quasi-engineering classes offered by experts in the field. Depending upon a shop’s workflow and the qualifications of its technicians, either of these training levels will improve productivity for modern shop technicians.

Training and Efficiency

Obviously, today’s master technician is a logical and critical thinker. The old diagnostic method of associating a symptom with a specific component failure or “symptom diagnosis” rightly belongs in the Model T Ford era where it began. Modern technicians must understand how to access, assimilate and apply abstract information in order to achieve diagnostic accuracy and perform quality repairs.

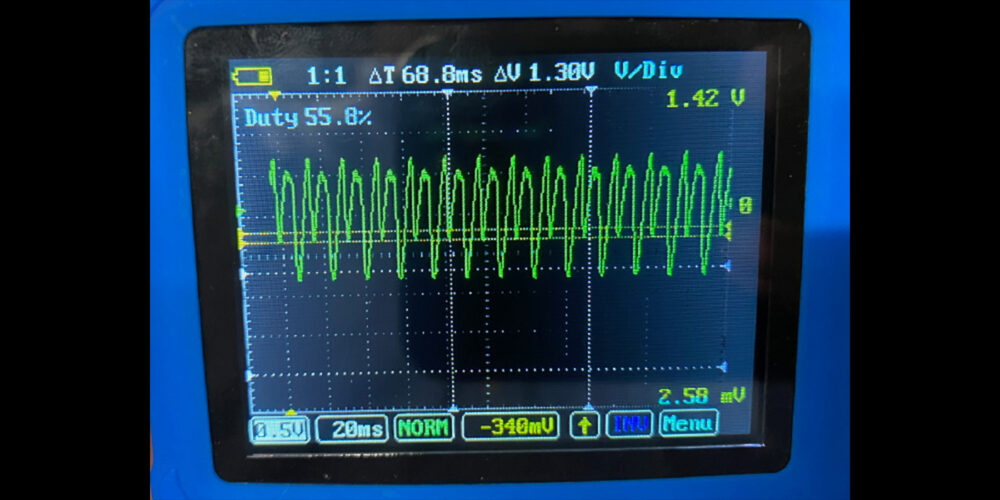

A good example might be diagnosing a cranking, no-start, no-spark failure in a mid-1990s import.

These systems had three basic parts: the ignition coil, magnetic distributor pickup coil and the ignition module. Since the ignition module is usually the most failure-prone but also the most expensive, the tech would want to make sure that replacing the module will solve the no-spark problem.

The “systems” test is very simple. The tech attaches a voltmeter to the coil and watches for the voltage value at the coil’s B-minus terminal to vary as the engine is cranked. If a voltage variation or “dwell angle” is present, the module is good.

If not, the pickup coil needs to be tested for resistance and voltage output to ensure that it’s capable of “triggering” the module. If the pickup coil is good, the module can be replaced by the process of elimination. If the pickup coil and module are “triggering” the ignition coil, but the coil isn’t producing a spark, then the coil is faulty.

That’s a simple explanation of how to diagnose a no-spark issue on 10-year-old technology. But any parts professional can relate horror tales of shops attempting to diagnose this very same condition by swapping and returning unused parts in torn, greasy cartons.

With “systems” knowledge, the tech can diagnose the no-spark complaint in minutes. Without systems knowledge, he’s condemned to making educated guesses by changing parts until the engine starts. The efficiency comparison of minutes to hours to solve the same problem is obvious.

Shop Math

Mechanics and lawyers live by the same economic yardstick, which is hours billed. A shop is considered 100% efficient if it bills eight hours for each eight-hour work day. A well-managed shop, however, normally operates at 125% efficiency, billing 10 hours per eight-hour work day.

How is such efficiency possible? First, most work is billed according to the amount of time that it takes an average mechanic to perform the specific service or repair in an average shop environment.

Second, excessive amounts of repair time can be wasted with 1) the tech printing out service information, 2) understanding the repair procedures, and 3) finding the correct tools to do the job. Needless to say, each time the tech performs the same type of service on the same model of vehicle, the faster he becomes because 1) he no longer needs to print out service information, 2) he’s now familiar with the repair procedure, and 3) he knows exactly which tools work best for this particular repair.

Now, let’s look at a tech becoming familiar with new vehicle technology. The only way a technician can learn about new vehicle technology is to read service information, watch training videos or attend a product introduction class taught by an experienced instructor.

Of course, attending a class doesn’t mean that the tech has achieved any level of proficiency in performing the repair. But the material in the class provides an overview of the operating principles, diagnostic procedures, repair procedures and the tooling and equipment needed to complete the repair.

Quite clearly, a well-managed shop masters new vehicle technology by training its technicians. A poorly-managed shop, on the other hand, usually relies upon second-hand information obtained from other shops or it simply tries to stumble through a repair on a trial-and-error basis. This is why many poorly managed shops average only 5.6 billable hours per day and why many well-managed shops average 10 and sometimes 16 billable hours in an eight-hour work day.

Cost of Doing Business

Over the years, jobber training clinics and other “free” training venues have created the impression that “training” should be “free” to any shop that participates.

The current training reality is that researching, composing and presenting information on highly complex systems is so high that very little technical training should be regarded as a free service to participating shops. Quite to the contrary, training is a fixed business expense that should be included in the shop’s overhead just like heat, lights, and insurance.

Shop owners and technicians must also change their attitudes toward training.

Many shop owners are fearful that training their technicians will allow those techs to seek better jobs elsewhere or will lead to demands for increased compensation packages.

In the same sense, many technicians fear that training will expose their short-comings. Many assume that they can learn specific vehicle systems through “on-the-job training” or through an expensive trial-and-error learning curve. Either attitude is self-defeating and will ultimately render both the technician and the shop for which he or she works ineffective in today’s technical climate.

Obviously, changing an industry’s attitude toward training involves solving peripheral issues like technician compensation and managing the increasing cost of doing business.

The independent service sector has its work cut out in changing attitudes and creating working conditions that attract and retain talented people. But without change, America would still be rolling on the wooden wheels of a Model T Ford.

Training is all about attitude and we, as an industry, must be willing to change right along with it as the vehicle technology that we must deal with evolves to meet the challenges of the future.