Remember the old days? You’d occasionally see a customer drive into your shop holding a string. It was attached to the carburetor linkage, through one of the hood louvers and over the top of the windshield so he could control the throttle.

Drive by wire had a different meaning back then. Mechanical linkages connected the throttle control inside the car to the carburetor or fuel-injection throttle body on the engine. Sure, the concept worked – and allowed for some pretty interesting roadside fixes – but today’s systems are much more precise, efficient and dependable.

Since BMW introduced its version of drive by wire in the 1988 7-Series, mechanical linkages have been going away. Today, the old throttle cable is almost nothing more than a memory. Virtually every vehicle manufacturer has an electronic throttle system on every make and model.

Electronic throttle control (ETC) has been responsible for improving fuel economy, reducing emissions, protecting powertrain components and providing a better overall driving experience.

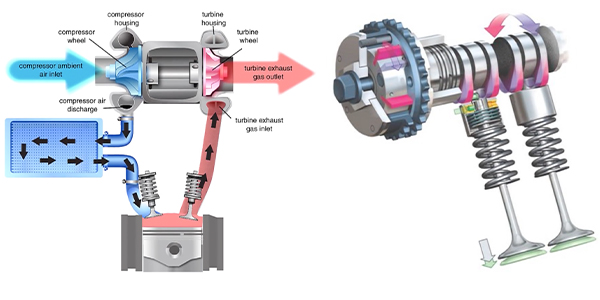

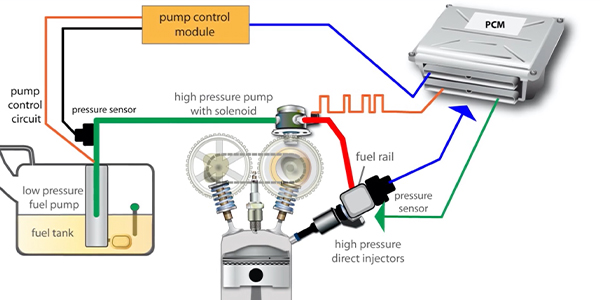

Regardless of the vehicle, electronic throttle controls typically involve two different components: the accelerator pedal position sensor (APP) and the powertrain control module (PCM) that control the electronic throttle body.

The accelerator pedal position sensor is the driver’s input to the PCM. In the old days, of course, when the driver pressed the gas pedal, it would pull on a cable that was physically connected to the throttle blade. There was a Throttle Position Sensor (TPS) attached to the throttle blade which would report the request to the PCM along with feedback as to the actual position of the throttle blade.

On ETC vehicles, the driver still presses on the accelerator pedal, but in most applications, there is no longer a cable attached to the pedal. Instead, there is now an APP mounted to the pedal.

The APP will likely incorporate a calibrated spring assembly, so the driver has the familiar feel when pressing on the accelerator pedal. But the APP will consist of 2 or more sensors which act as an input device to the PCM or the ETC standalone module on the throttle’s position. It is important to have multiple inputs present for failsafe measures. Since this is a critical input for safety, there is a system of checks and balances in place to prevent unintended acceleration, or no acceleration.

The throttle body does the actual work but because of the complexity of the system, faults can occur. These faults can be frustrating for the motorist, the service advisor and the technician because even if an intermittent fault happens for just an instant, it may result in a “limp-in” condition for the customer.

Some of the concerns customers with ETC system faults may have can include inoperative cruise control, vehicle stuck in limp-in mode or illuminated warning lights.

However, it is also important for your technician to remember that other areas of the vehicle’s control system may cause throttle-related problems that aren’t necessarily caused by the electronic throttle control system. Faults such as wheel speed sensors could affect throttle opening and should be diagnosed first

The Electronic Throttle Control system offers many parts replacement opportunities. Electronic Throttle Bodies (ETBs) have high O.E. failure rates and when the original parts fails, it can impact the vehicle’s power, fuel economy, and drivability.

Sure, it might be easier to diagnose a broken throttle cable than an electronic or wiring problem, but this is today’s world and today’s technology. It’s better than it ever was, and your customers benefit from your shop’s skill and knowledge.

This video is sponsored by The Group Training Academy.