Technology continues to evolve across the entire spectrum of the automotive industry and it’s an extremely exciting time. With ADAS, regenerative braking, variable valve timing, hybrid electric powertrains – there’s certainly a lot to keep up with!

The steering system on vehicles is one of the most critical links between the driver, the vehicle, and the road. The means of keeping a vehicle pointed in the direction the driver intends, in nearly all driving conditions the driver and vehicle face, continue to improve.

For the past 15 years or so, one of those means has been a shift in the automotive industry from hydraulic power steering to electric power-assisted steering, or EPAS. Considering all the benefits, it’s easy to see why. Electric power steering not only reduces the effort required to steer a vehicle like traditional hydraulic steering does, but it also makes the vehicle lighter, it contributes to better fuel economy, and it’s easier to install.

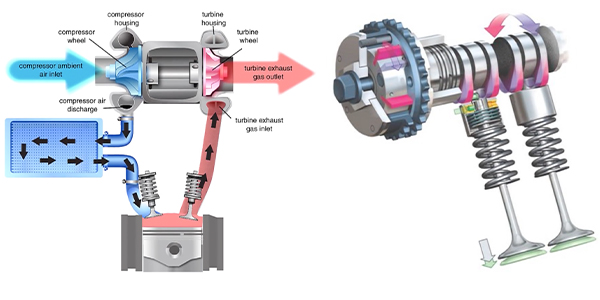

In an electric power-steering system, an electric motor is either bolted to a steering column, to a steering rack, or to a hydraulic power steering pump. The system has a torque sensor that measures the amount of force applied to the steering wheel, and that sends a signal to the power-steering control module. Meanwhile, the control module is getting vehicle-speed information from the CAN BUS network, and it’s taking these inputs into consideration to determine just how much assist to provide to the driver.

The bottom line is that electric power systems are more than a rack and motor – they’re sophisticated, highly connected systems that bring safety and reliability to your customers.

You’re going to see more and more of them. It’s estimated that by 2025, nearly half of all steering repairs will be to EPAS systems. Why?

Well, an on-demand system improves fuel economy and reduces excess heat.

It allows steering assist in engine off conditions such as with hybrid vehicles

Modern safety features like lane correction and collision avoidance systems utilize EPAS

Parking assist and trailer backup systems require EPAS

Autonomous vehicle technology relies on electronic steering

And, with the exception of electronic hydraulic power steering systems, EPAS eliminates components that can be contaminated, including the fluid, hoses, pumps, belts and pulley.

With so many great benefits, what can go wrong? Here are four common failures you may encounter:

Water Ingression occurs when the unit is not properly sealed, and water is able to get inside the unit causing contamination, electrical problems, and rust.

Belt-driven EPAS racks have an internal belt to transfer the torque from the electric motor to the rack bar via a ball screw assembly. This belt can wear, stretch, strip or break causing loss of assist.

A Torque Sensor Failure will give incorrect input data to the Power Steering Control module (PSCM) leading to improper assist and diagnostic trouble codes (DTC).

CAN Network may face communication issues, whether it’s the PSCM or another module not able to communicate on the bus, which leads to DTCs, loss of assist and PSCM lockout.

When values or inputs are not within specification, the PSCM can use preprogrammed values to give reduced assist to the driver. A DTC will be set triggering the Malfunction Indicator Light (MIL).

Although some units may be considered plug-n-play, others are not. Even on “Plug-n-Play” units, a software update is recommended – and the software is often only available from the O.E through a subscription! Don’t think it might not happen to your customer – an estimated 60% of vehicles in operation require a control module update!

Your techs and service advisors will need the proper tools and training to diagnose the problems and explain them adequately to your customers. The good news? Resources are out there. For more information, visit BBB Industries.

This video is presented by The Group Training Academy.