“One of the biggest mistakes I’ve seen over the years starts with an auto technician being unhappy with the performance of his or her air impact wrench,” explains Eric Garbe, Senior Automotive Technical Writer for TechShop Magazine. “To make matters worse, there’s always a certain aura surrounding this tool, and whomever owns the most powerful one in the shop holds sort of bragging rights over everyone else.”

In an article originally published in TechShop, Garbe explains the unfortunate reality that, in most cases, air tools rarely live up to expectations and, even if a new one happens to work better than an old one, it’s probably still not at full capacity, a fact often unbeknownst to the owner.

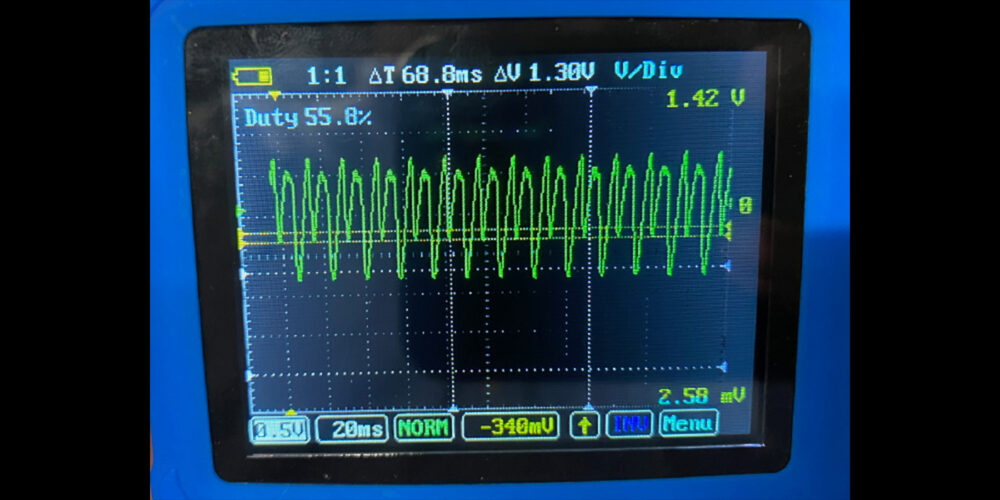

“The reality is that most likely your air tools are not getting the correct pressure and volume, and regardless of the pressure at the compressor, rarely are they subjected to higher-than-needed pressure. The key lies in static versus dynamic air pressure,” Garbe says.

“Static pressure is the amount available in the line when nothing is operating. When you read the gauge on the compressor, it’s easy to think this is what your air tools are operating at, and if you were to check the pressure at the end of your air hose, you would see the same reading. But this is only the static pressure,” he teaches.

“Dynamic pressure, on the other hand, is the pressure available at your air hose when an air tool is connected and running. Air tools require a large volume of air to operate as intended, and it’s not uncommon to see static pressures drop by 30 psi or more when taking a dynamic reading,” Garbe says. “The reason for this is volume. If your airline can’t flow enough volume, you’ll never be able to maintain the proper pressure for correct air tool operation.

Garbe explains how to determine what you have, what you need and how to bridge the difference. Read the complete article HERE.