I have a quiz for you. Has belt tension increased or decreased in the past 20 years? The average belt tension used today IS lower with vibration control and the integration of the Litens OAD (Or overrunning alternator decoupler). As a result, less tension increases the life of the belt by slowing down wear.

This has permitted OEMs to extend replacement intervals past 100,000 miles on some vehicles. Also, with less tension, the amount of power required from the engine to turn the belt drive system is lower, improving fuel economy. With advent of newer technologies like alternator decouplers and better belt compounds, OE’s are able to reduce overall tension on belt drives that otherwise would have been higher had these new technologies not existed”.

Keep in mind that going from V8’s in the past to smaller displacement engines like I-4’s and 3 cylinders, have created the need for vibration control products. Otherwise you would have the need for really high tension to control the more torsionally active small engines.

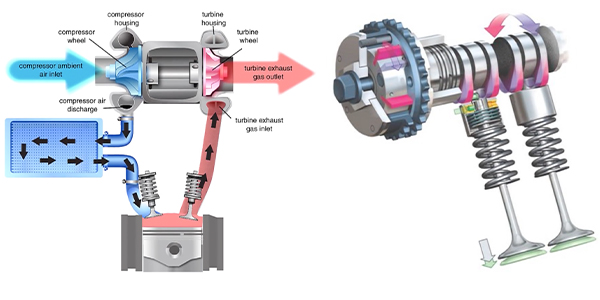

Less tension increases the chances the belt system could flutter or slip when loads on the belt drive system change or the engine’s speed increases or decreases. To combat belt flutter, many OEMs have started to use components like decoupler pulleys.

A decoupler pulley can decouple the alternator from the belt drive system and help absorb small vibrations from the crankshaft that could produce belt flutter.

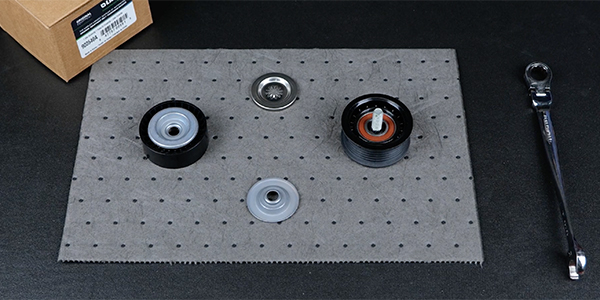

Decoupler pulleys are a “wear” item and on some vehicles, it is recommended that it is replaced along with the belt. Why? Inside the decoupler pulley is a spring which will fatigue over time. There is a ball bearing which also wears out due to grease exhaustion. The third failure mode is grease exhaustion of the clutch grease.” The same is valid for belt tensioners.

In this rare case of automotive engineering, less is actually more when it comes to belt drive system tension.

This video is sponsored by Continental.