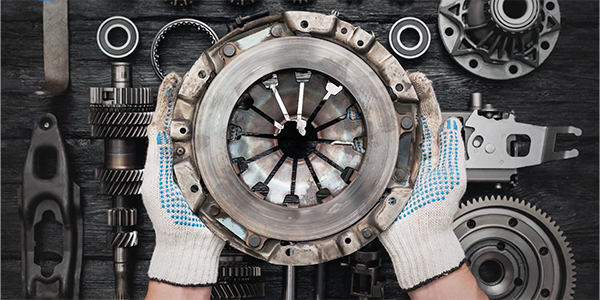

The clutch is the heart of manual transmission performance and replacement is typically a straightforward job. However, sometimes new issues can be created if a tech is in a rush and is not paying close attention to the installation process.

This tech tip is the result of a common tech installation error following clutch and pressure plate replacement.

Proper alignment of the clutch disc and the pressure plate to the flywheel is a critical part of a successful clutch replacement. This can be achieved with using the correct alignment tool.

In addition, there is another alignment that can be overlooked when servicing some GM clutch replacement kits. The pressure plates on these kits have drive strap rivets that can cause the transmission to stay disengaged if not properly lined up with the reliefs in the flywheel. Unfortunately for a technician not paying close attention the pressure plate bolts can still be installed and torqued to specifications. Essentially this “locks” the pressure plate to the flywheel rendering the clutch disc useless. The only solution to fix this is to remove the pressure plate and reinstall correctly on the flywheel.

And lastly, never use an impact gun to tighten the bolts on a pressure plate. Always use a torque wrench and tighten the bolts as directed in the correct sequence instructed by the service procedures.

Remember, not all clutches are the same and not all installation procedures follow the same set of install instructions. It is important to review all service information and carefully inspect all new components prior to replacement to ensure a simple mistake doesn’t make you do the same job twice!

This video is presented by LuK.