You have a choice to make for your customers. You can sell them a product that will require maintenance and uses old technology, or you can sell them a maintenance-free product that takes advantage of the latest materials and engineering.

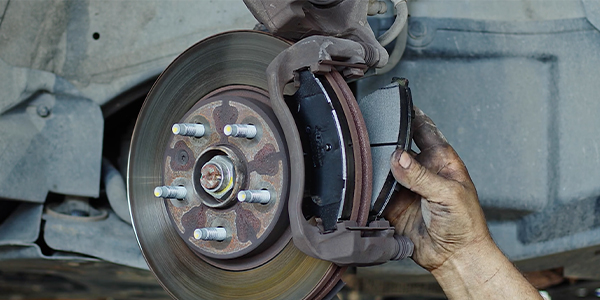

The choice is obvious, by selling a better product that requires less maintenance to the customer, you will gain their future business and trust. So why do some technicians and drivers think a grease fitting is the answer to better suspension components? For some reason, some technicians still believe older style replacement suspension parts with grease fittings and metal on metal balls and sockets are better than a maintenance-free sealed joint with an engineered polymer socket.

But, judging a joint by a grease fitting or the lack of a grease fitting is not an accurate way of evaluating a replacement ball joint or tie rod end. It would be best if you looked inside the joint to understand why OEMs stopped using grease fittings and why these types of joints are not a smart choice for modern cars and trucks.

In 1970, an oil change was called an “oil and lube” service. While the car was up in the air or over a pit, a mechanic would grease the suspension joints. Greasing the joint did two things. First, pumping in new grease replenished any grease lost to oxidation because of the heat generated by metal to metal contact. Second, as grease is pumped into the joint it flushes out contaminates as well as small pieces of the metal caused by wear to the ball and socket. It could be a messy process.

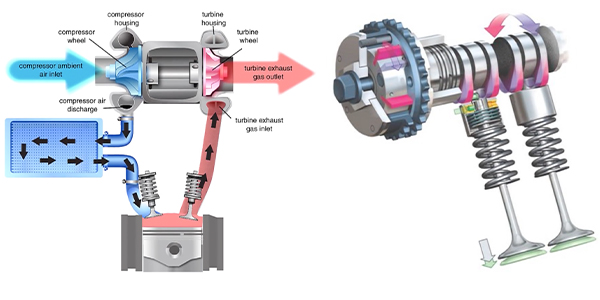

Over the next 50 years, the polymer compounds evolved. Material science engineers were able to formulate polymer compounds that could take hard impacts, resist wear and withstand high temperatures. Automotive engineers saw a potential application for spherical suspension joints. They realized these polymer materials could be formed into sockets for ball joints. With the correct lubricant and surface finish, these could outlast metal-on-metal joints. At the same time, new rubber material and designs for boots were advancing. These boots kept the grease inside and outside contaminates out.

Grease also evolved! Old-school chassis grease was often made from oil and natural additives to thicken the final product. Today, the average general-purpose chassis grease found in grease guns has ingredients like zinc, graphite and lithium. But, the engineered greases inside a sealed joint is much more sophisticated. Sealed joints will use silicone and fluorether-based greases with additives like Teflon, molybdenum and additives engineered at the molecular level. These synthetic greases can eliminate wear to the metal stud and polymer sockets under extremes of heat, pressure and other outside forces.

Do you still think metal-on-metal joints are better for your customers? Here is something to think about, “extended oil change intervals.” For some vehicles, the factory recommended interval is 7,000 to 10,000 miles. If a ball joint or tie rod end is not lubricated during the oil change, it means that a joint will have to go 14,000 to 20,000 miles without being greased! The grease could oxidize or leak out of the boot before the next oil change. This could cause the joint to wear out rapidly. With a sealed joint, the driver could go 100,000 miles or more without any maintenance what so ever.

Even if you are still loyal to greaseable joints, some modern suspension designs do not have room for grease fittings! Even if there is an application with a grease fitting, it might require a special adapter to grease the joint. While some aftermarket suppliers still produce greaseable joints, OEMs and OEM suppliers like CTR agree that the reality is that sealed ball joints and tie rod ends are the more advanced product that will last longer. Just like the OEMs, CTR uses engineered polymers for its aftermarket joints. These joints have greater durability and longevity when compared to greaseable metal-on-metal joints.

CTR uses its 50 years of OEM supplier experience to engineer high-quality polymer joints for the modern vehicle. It knows engineered polymer joints are the right choice for modern vehicles because it has 50 years of OEM supplier experience. That knowledge of high quality and technology translates into a genuine OEM quality part.

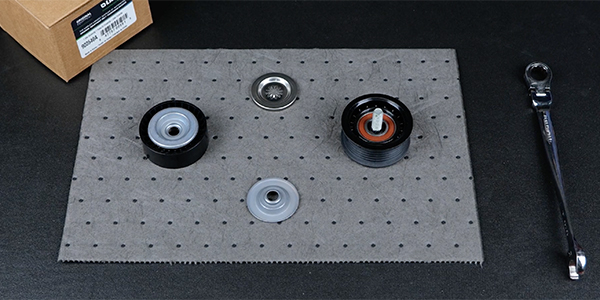

CTR’s ball joint line covers more than 24 OEMs with more than 900 part numbers. The catalog includes coverage for domestic and import manufacturers. CTR’s catalogs for suspension parts like bushings, stabilizer links, control arms and bushings are constantly being constantly updated with new applications announced monthly.

This video is sponsored by CTR.